Every day it seems that the number on tariffs are changing but regardless of the percentage, local manufacturers are being affected. Some are for better and some are for worse.

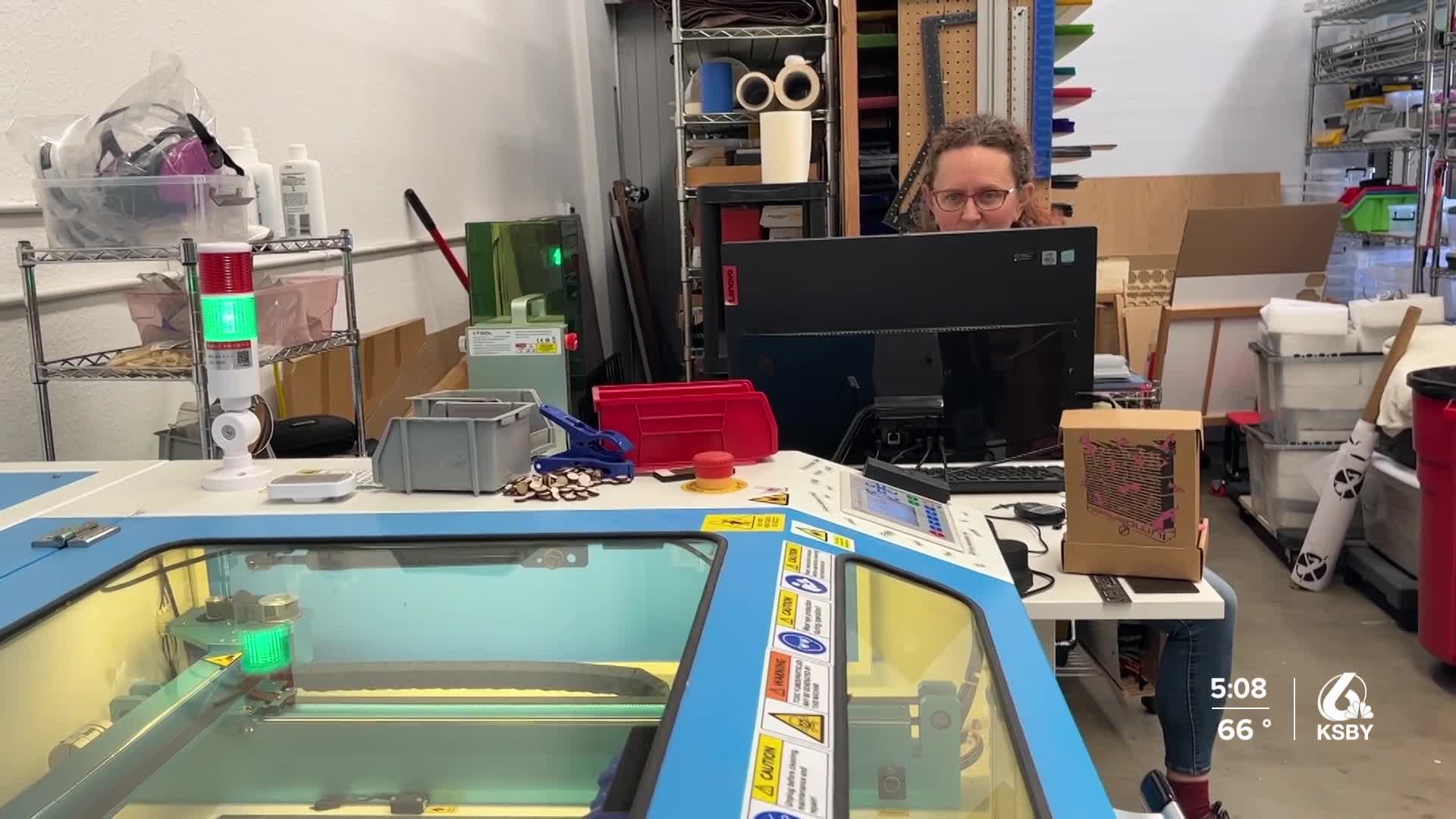

A walk into local manufacturer Alpenglow Industries reveals knick knacks, a functional laser cuter and rows upon rows of different materials to make electronics and different tools.

Many of the materials owner and founder Carrie Sundra buys for her business hail from China, mostly because the pricing on domestic parts have increased dramatically.

A few years ago, Sundra used to be able to buy domestic even though it was a little more expensive but now it's to the point where the margins don't make sense for her to buy in the country for a circuit board.

“It was a little over $6 in China versus $26 [here]," Sundra explained. "So I'm saving like about $20 per board and I'm ordering 100 boards at a time. That adds up.”

Even with tariffs, she says she’s still paying less than she would be if she were buying domestically.

But according to Sundra, the biggest threat to her small business right now is the de minimis exemption, which is set to be eliminated May 2.

The de minimis exemption allows small businesses like Alpenglow Industries buy $800 or less of imports without an additional tariff. Meaning those smaller orders aren't getting taxed but after May 2, they will be.

“Everything is going to cost me double," she said of her orders from China.

However, another manufacturer in San Luis Obispo, Maglio Inc., shares a different notion.

“We pretty much try to source everything domestically, wherever possible, even if there's a 10 or a 20, 30% markup versus an international product coming out of Asia," Maglio Inc. President Ted Thayer said.

Thayer’s company makes everything from custom products, prototypes and precision parts for assembly sourcing materials from all over the country. He says even though he pays more than he would overseas, he gets better price breaks and the materials get to him quicker. He says it also creates a stronger domestic economy.

“We really feel that by buying domestically and helping the domestic industrial base grow and compete successfully, everybody benefits across the board,” Thayer explained.

Thayer says that half of their contracts are from the Department of Defense, so for those, materials are required to come from the U.S. but for now, both Sundra and Thayer are continuing to work away in the hopes their businesses will find a way to thrive amid the uncertainty.